What are the types of acrylic sheets?

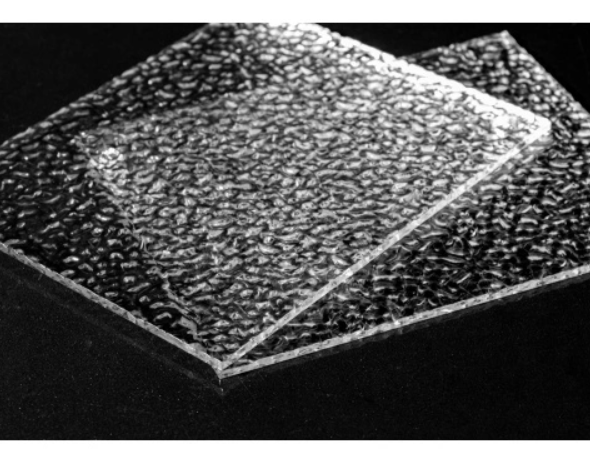

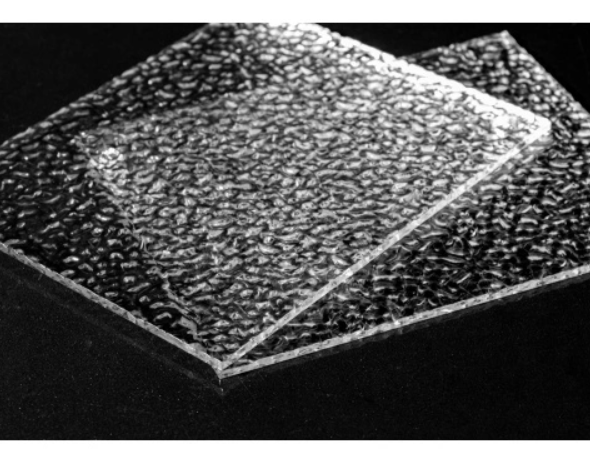

1. Press light transmittance The Pmma Sheet can be divided into transparent plates, translucent boards (including chromosome transparent plates), and color plates (including black and white and color plates). 2. According to the performance division The Acrylic Sheet can be divided into anti -impact boards, anti -ultraviolet plates, ordinary boards and special boards such as high -resistant punching boards, flame retardant boards, scrubbing, metal effect boards, high wear resistance boards, light boards, etc. 3. Follow the production process The Acrylic Plate is divided into casting plates and extrusion plates according to the production process. (1) Casting plate: High molecular, excellent stiffness, strength and excellent anticippling performance. The characteristics of this board are small -batch processing. It has an irresistible flexibility in terms of color system and surface texture effects, and the product specifications are complete, which is practical for various special purposes. (2) Squeezing board: Compared with the casting plate, the molecular weight of the extrusion plate is low, the mechanical properties are slightly weak, and the flexibility is relatively high. However, this feature is conducive to bending and heat -shaping processing, and the softening time is shorter. When dealing with large -size plates, it is conducive to various fast vacuum -sucking molding. At the same time, the thickness tolerance of the extrusion plate is smaller than the casting plate (casting: 1.8mm-300mm, squeezing: 0.5-12mm). Because the extrusion plate is a large number of automated production, the color and specifications are inconvenient to regulate, the diversity of product specifications is limited. 4. Request regeneration board Ackli also has a regeneration board called recycling acrylic edge material. After the heat degradation, the regeneration MMA (methyl acrylic) monomer is obtained, and then the chemical aggregation reaction is obtained. After strict process processes, a pure MMA monomer can be obtained again, which is not different from the new synthetic monomer. However, the degradable monomer produced is not high. After the board is formed, its quality and performance are poor.